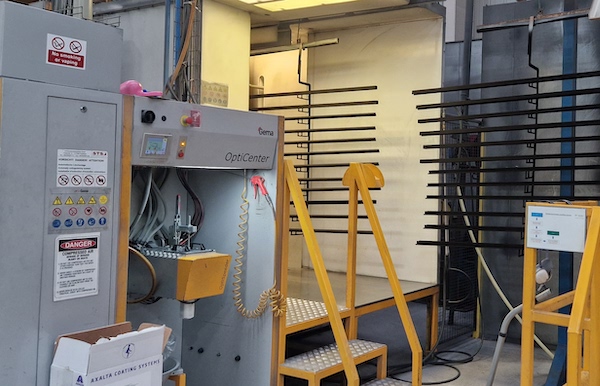

Komfort’s Powder Coating Service and Facilities

Komfort is the manufacturer of the powder coating applications to suit interior office space ranges of relocatable partition systems. The team at our Birmingham factory powder coat all Komfort’s partitioning elements as an in house service, but we also work with other metal manufacturers in the area.

The company guarantees that all powder coated components will retain compatibility for a period of not less than ten years from introduction.

- Product maintenance, all materials and components must be clean, free of lubricating oil and in good condition.

- All inspection & test equipment are calibrated by an approved UKAS accredited centres annually or any agreed frequency levels to ensure calibration tolerances are maintained, machinery tools and dies required to manufacture the range of partition systems are the sole property of the company.

- However, the company reserves the right to change and improve the application process of some or all of the components when required to improve performance or comply with current legislation.

- Komfort reserves the right to inspect all materials during the warranty period.

- In the event of a claim being made against the warranty we reserve the right to inspect the materials or components with a view to mitigating any claim before corrective action is taken.

Komfort supplier powder application specifications:

- Polyester Architectural semi-gloss, formulated for application on aluminium extrusion and sheets, steel and galvanised steel substrates.

- Delta E (Colour) Maximum – 1 ∆E.

- Gloss – 30% ± 5% (35% – 25%)

- Coating thickness – 70 ± 10 microns

- Colour ranges – Ral & BS standards

- Powder application – Architectural

- Curing condition – 10 – 25 min @180 degrees celsius

- Density – 1,2 – 1,7 g/cm3

Free issued powder must fall within the above parameters

We offer the colour ranges below as standard and welcome any RAL or BS colour ranges.

- Grey – 00A05

- Silver – RAL 9006

- White – RAL 9010

- Black – RAL9005

Subcontract work (where applicable) will be approved by samples prior to commencing production, approved samples will be kept and used as reference swatches. Manufactured materials will be subject to Komfort’s approved standards and meet the following specifications below:

- Delta E (Colour) Maximum – 1 ∆E.

- Gloss – 30% ± 5% (35% – 25%)

- Coating thickness – 70 ± 20 microns